Using AI to control energy for indoor agriculture

30 September 2024

Published online 9 September 2013

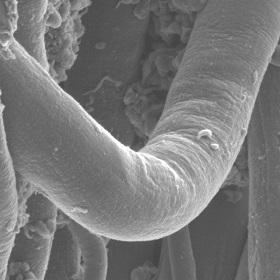

Spider silk has several structurally beneficial properties that may be attractive for use in electronic devices, such as great strength and flexibility, but its use in electronic applications depends on its compatibility with conductive materials. Eden Steven and colleagues, including Wasan R. Saleh from Baghdad University, have developed a synthetic procedure for the coating of spider silk with conductive carbon nanotubes, and describe their method in Nature Communications1.

When exposed to water, the tough spider silk softens and contracts. The researchers mixed spider silk with a powder of carbon nanotubes and exposed it to a few drops of water. They then pressed the mixture between Teflon sheets to apply a shearing strain. When dried, the spider silk turned black and contracted in length, covered uniformly by the carbon nanotubes.

This material has improved toughness compared to the uncoated fibre whilst also being electrically conductive, with conductivity dependent on physical strain of the thread and also humidity. Through the demonstration of various sensors based on this material, including a heart pulse sensor, it is hoped these results will aid further development of spider silk-based electronics.

doi:10.1038/nmiddleeast.2013.151

Stay connected: