Special Issue: Water Narratives

24 December 2025

Published online 28 April 2016

New studies carry potential for creating much more efficient water desalination systems in the Gulf.

© KAUST

This is compounded by an exponential population growth and industrial development. The average fresh water availability in the region now is on average 90-100 cubic metres per capita per year which has prompted GCC governments to increase spending to combat water scarcity and ensure sustainable resources for the future3.

Currently, two conventional desalination methods are used for seawater desalination: thermally-driven multi-effect desalination (MED) and pressure-driven reverse osmosis (RO).

Thermally-driven desalination processes use evaporation-condensation processes. The evaporated vapours are condensed as pure water and highly concentrated brine is ejected from the bottom of each evaporator system.

Thermal desalination systems are normally combined with power plants to operate as a co-generation system.

On the other hand, in pressure-driven (RO) desalination processes, the high pressure seawater feed is passed through semi-permeable membranes to overcome osmotic pressure. The membranes allow only the water to pass through, leaving dissolved salts behind in the “reject stream”.

Thermally-driven desalination processes are are used in about 70% of GCC installed desalination capacities. They’re better suited to the Gulf’s high temperature, salinity, and turbidity, along with the frequent occurrence of hazardous algae bloom that not only require high pre-treatment costs but cause frequent fouling of pressure-driven desalination processes.

But can these thermally-driven methods meet the increasing need for water in GCC countries?

In the Gulf, seawater desalination capacities are expected to rise from the current 3,400 million cubic metres to 7,000 million cubic metres in 2020 to meet the demand generated by industrialization and development.

GCC governments have earmarked more than $100 billion for investment in water sectors between 2011 and 2016, announcing plans to invest another $300 billion in water projects by 2022 to meet growing water demand4.

It follows that, with the current mix of pressure and thermally driven desalination techniques, the energy investment will also double. This will cause carbon emissions to nearly double by 2020. In most of the GCC, the average annual carbon emission is already higher than world average of 9 kilotonnes per capita5.

A sustainable form of desalination requires countries to exert major efforts to be able to meet the agreed carbon emissions targets put forward at the COP21 meeting in Paris last December. This would include gradually improving the efficiency of seawater desalination processes and researching innovative methods to produce potable water at low energy for Gulf countries6.

Thermally and pressure-driven conventional desalination techniques are not only energy intensive but are unfavorable for the environment. For example, RO processes consume 3.5-5 kilowatt hour electric energy for one cubic metre of water production while MED can consume four times as much due to operational limitations7-10.

We analyzed the selection of desalination plant of water production of 2,813 cubic meter per hour (m3/h) for a large size community. The planner has two choices: thermally-driven desalination cycle combined with power plant or standalone pressure-driven system operated by electricity.

The efficiency of desalination processes is usually measured by a performance ratio (PR) that counts the numbers of kilogrammes of water produced per 2,326 kJ of heat consumed.

For this specific water production, the conventional thermally driven system of performance ratio 11 needs input steam from power plant at a rate of 70.83kg per second to produce the required amount of water. This steam is bled from low pressure turbines in power plants.

Arguably, if this bleed steam continues to expand through the turbines, it can produce a further 28.46MW of electricity. The same amount of water can be produced by an RO plant (at 5 kWhe/m3) with only 15MW electricity.

Our hybrid MED-AD cycle has the lowest water production cost ever reported.

On the face of it, in the current state, the RO with a power plant configuration is more energy efficient than conventional MED system (a PR of 11) combined with cogeneration system to produce required power and water. But this is not the case.

The poor performance of MED system was always attributed to limitations in the first and last stages of the process. However, recent advent in thermally-driven research has improved the performance of new class hybrid MED cycles several folds higher. Scientists overcame these conventional limitations with the introduction of nano-filtration (NF) processes and solar-energy driven adsorption cycles (AD)11-16.

Nano-filtration removes fouling and corrosion components from seawater feed and AD cycle integration break the last stage temperature limitation, enabling hybrid NF-MED-AD performance ratio to achieve new levels of energy efficiency (a PR of 25).

An MED requires heat sources across different stages of operation — at the first stage it utilizes the bleed steam from power plants, while in its last stage, it’s operated using water-cooled condensers that are very much dependent on the conditions of the operation’s location.

Because temperatures in the Gulf are around 45°C during summer, this limits the operation range of an MED to 70°C at the highest and 45°C at the lowest, forcing conventional MED systems to be installed with only six to eight evaporators or stages. However, the new class hybrid NF-MED-AD cycle’s first stage can operate at 125°C and its last stage as low as 10°C, extending number of stages to more than 25.

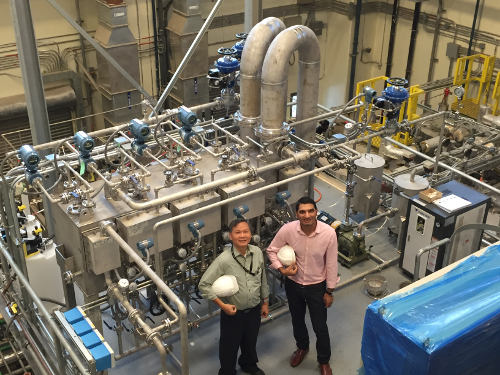

To demonstrate this concept, a MED-AD hybrid pilot, with a nominal water production of 10 m3/day, is now being commissioned by the King Abdullah University of Science and Technology (KAUST).

The hybrid pilot is expected to double the amount of water production, due to the thermodynamic synergy of two thermally-driven cycles which can be exploited to their full potential, using the same heat input that a typical MED consumes17-20.

The heat for regeneration of AD adsorbent can be supplied from solar energy available in abundance in the region.

Based on hybrid cycle results and international desalination association costing data, a Life cycle analysis (LCA) has been conducted by the authors for a large-scale plant of 100,000 cubic metre water production per day.

It has found that the MED-AD cycle has a production cost of less than $0.5/m3 compared to conventional MSF, MED and RO as $1.20, 0.99 and 1.20 respectively 21,22.

In other words, our hybrid MED-AD cycle has the lowest water production cost ever reported. These cycles can be easily retrofitted to the existing thermally-driven plants, boosting water production to several folds without increasing energy input23.

Thus, they have a great potential to address issues of sustainable seawater desalination in GCC regions.

Authors' affiliation: Water Desalination and Reuse Research Centre, King Abdullah University of Science & Technology, Thuwal, 23955-6900, Saudi Arabia.*Kim.ng@kaust.edu.sa

doi:10.1038/nmiddleeast.2016.50

Stay connected: