Using AI to control energy for indoor agriculture

30 September 2024

Published online 24 May 2019

Selectively permeable glassy polymer membranes could allow abundant but impure natural gas to be tapped by removing the key impurities.

Yang Liu

“Over 40 per cent of known natural gas reserves in the United States are sour,” says KAUST chemical and biological engineer, Ingo Pinnau, emphasising the importance of inexpensive, energy-efficient and effective methods that can clean (sweeten) sour gas. In the Middle East, up to 20 per cent of gas reserves are sour. The problem affects many other gas reserves worldwide.

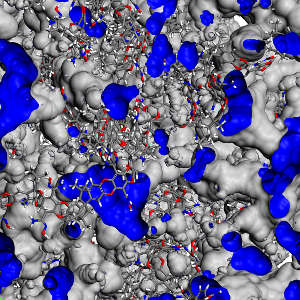

The membranes developed by the team are based on an organic amidoxime polymer with varying chemical modifying groups attached. The membranes’ porous structures result in highly selective permeability, especially for the most troublesome H2S molecules. Tests demonstrate that H2S and CO2 can selectively permeate through the membranes from a high-pressure stream of sour gas.

Pinnau says the innovation came together when his own earlier work on developing selectively porous membranes was combined with the expertise and state-of-the-art facilities for handling high pressure and toxic gas streams at Georgia Institute of Technology.

The collaborators now hope to improve and extend their membranes’ capabilities and move towards commercialisation.

doi:10.1038/nmiddleeast.2019.79

Yi, S. et al. Ultraselective glassy polymer membranes with unprecedented performance for energy-efficient sour gas separation. Sci. Adv. 5, eaaw5459 (2019).

Stay connected: