Using AI to control energy for indoor agriculture

30 September 2024

Published online 11 August 2020

Metal-organic frameworks have been used to make porous liquids and membranes for gas separation technologies.

Rafia Ahmad, KAUST (2020)

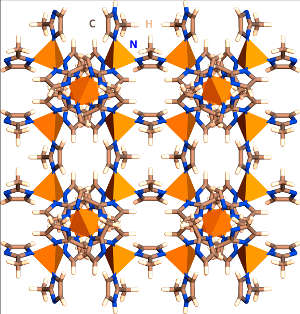

The secret lies with crystalline solids called metal-organic frameworks (MOFs), which have a highly porous structure assembled from metal ions or clusters connected by carbon-based ‘organic’ linker groups. The team found that modifying the surface of MOF nanoparticles with suitable chemical groups allowed them to form stable dispersions within a liquid solvent. The mixture of solvent and MOF behaves like a porous liquid.

The pores can be tailored to selectively adsorb specific gases. The team demonstrated their innovation by achieving the challenging separation of propylene gas from propane. This key industrial process currently requires energy-intensive distillation. Using the porous liquid offers a more efficient and environmentally friendly approach. The researchers estimate that using their MOF for this separation could save 0.1 percent of global energy production.

“In addition to using an empty MOF in a porous liquid for gas separation, we have also shown these porous liquids can be processed into mixed matrix membranes,” says Alexander Knebel of the research team, which could offer further flexibility for gas separation technologies.

The team now plans to scale up the technology to demonstrate its commercial potential and apply it to other important industrial gas separations.

doi:10.1038/nmiddleeast.2020.85

Knebel, A. et al. Solution processable metal–organic frameworks for mixed matrix membranes using porous liquids. Nat. Mater. https://doi.org/10.1038/s41563-020-0764-y (2020).

Stay connected: