Using AI to control energy for indoor agriculture

30 September 2024

Published online 8 August 2022

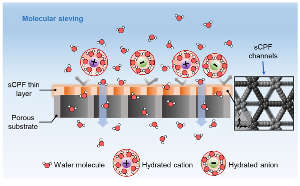

Membranes deposited from molecules in the gas phase allow fine control over pore structure for chemical separations and other applications.

Nature Materials https://doi.org/10.1038/s41563-022-01325-y (2022).

Yu Han, of the Advanced Membranes and Porous Materials center, at King Abdullah University of Science and Technology (KAUST) in Saudi Arabia, explains that most synthetic membranes demand a trade-off between permeability and selectivity, and it is very challenging to precisely control their nanostructure and porosity to separate molecules or ions of similar sizes.

“We developed a novel synthetic method to overcome these long-standing challenges,” Han says.

The team used chemical vapour deposition (CVD), in which gaseous precursor molecules are deposited on to a solid surface where they combine to form polymer membranes with very small, regularly arranged pores. The membranes are only several billionths of a metre (nanometers) wide. Their molecular layers stacked to form pores small enough to allow water molecules to pass, while blocking ions that were dissolved in the water — precisely what is required to purify drinking water from seawater, for example.

“Our membranes outperformed various state-of-the-art advanced membranes, showing great potential for applications in water desalination or purification,” says Han. He points out that industrial separation processes, such as distillation, evaporation and drying, are typically energy intensive, accounting for approximately 15% of global energy consumption. The new membrane-based technology offers a much more energy-efficient, and therefore cheaper and more environmentally friendly alternative.

Purification of chemical mixtures is just one of many potential applications. Han anticipates that the team’s chemical vapour deposition method could be easily adapted to make other classes of membranes with atomically precise porous structures for use in novel applications, including molecular electronics, optoelectronics and organic solar cells.

Dan Zhao, professor of chemical and biomolecular engineering at the National University of Singapore, who was not involved in the work, comments, “It has been the ultimate goal for materials scientists and membrane engineers to fabricate ultra-thin membranes with ordered porosity [and this study] provides an exciting breakthrough in this direction”.

To make the shift from lab-scale demonstrations to industrial applications, the researchers will now focus on upscaling fabrication of their membranes and improving their anti-fouling property, mechanical strength and long-term chemical stability.

“We will also develop methods to fine-tune its surface charge properties and channel sizes,” Han adds.

doi:10.1038/nmiddleeast.2022.45

Shen, J. et al. Fast water transport and molecular sieving through ultrathin ordered conjugated-polymer-framework membranes. Nat. Mater. https://doi.org/10.1038/s41563-022-01325-y (2022).

Stay connected: